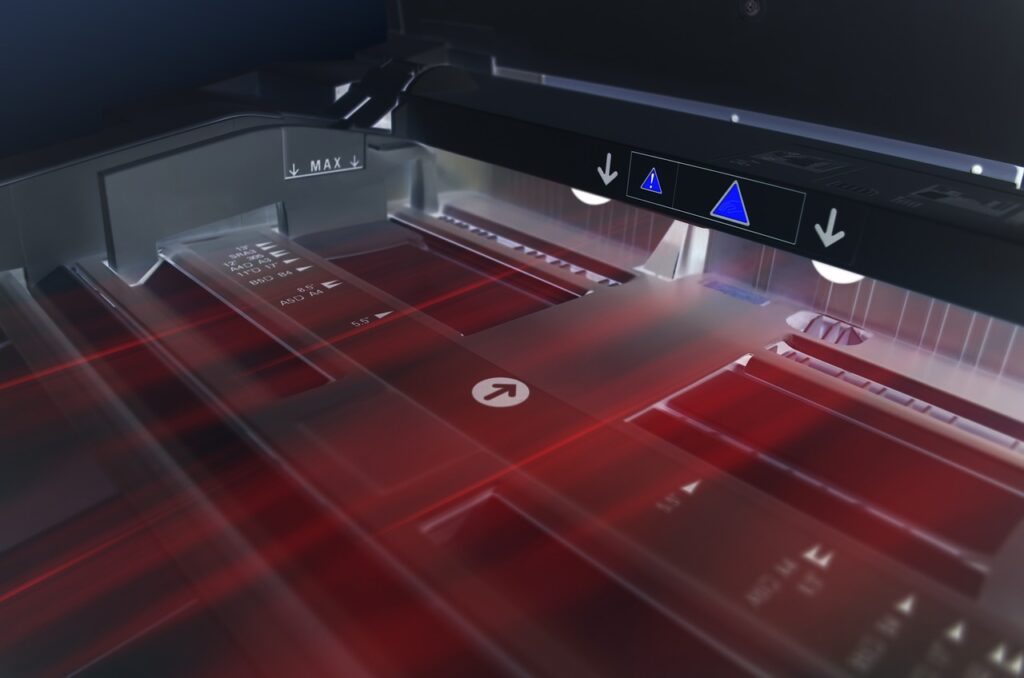

Digital printing is a modern method where digital images and graphics are printed directly onto different surfaces. Unlike traditional methods, it does not require printing plates, making the process faster and more flexible.

How digital printing works: The process involves sending a digital file (such as a PDF) to a printer. The printer then uses inkjet or laser technology to apply ink or toner directly to the print medium, which can be paper, fabric or other materials.

Common Uses and Applications: It is commonly used for business cards, flyers, posters, photos, brochures and personal marketing materials due to its ability to produce high quality prints in small quantities.

Table of Contents

Digital Printing vs Offset Printing

Key Difference: Digital printing prints directly from a digital file, while offset printing involves transferring ink from a plate to a rubber sheet and then onto paper. Offset printing requires more setup time and costs.

Cost Comparison: Digital printing is more economical for short print runs as it does not require setup costs. Offset printing becomes more cost-effective for larger print volumes because the setup costs are spread over many units.

Quality and speed comparison: Digital printing offers fast setup and is ideal for quick turnarounds, but can have color consistency limitations compared to offset printing. Offset printing provides high color fidelity and is best suited for high-volume, high-quality prints.

When to choose digital over offset printing: Digital printing is ideal for short runs, fast turnaround times, and projects that require personalization. Offset printing is perfect for high-volume jobs where consistent, high-quality color is important.

Digital Printing vs Screen Printing

Key Difference: Digital printing uses printers to transfer digital images directly onto the medium. Screen printing uses a mesh screen and stencil to apply ink layer by layer.

Cost and performance comparison: Digital printing is more cost-effective and faster for small quantities as it does not require screen making. Screen printing is more cost-effective for larger runs because the cost of making the screen is offset by volume.

Comparison of quality and versatility: Digital printing provides excellent detail and is perfect for complex images and color gradients. Screen printing offers vibrant colors and durability, making it ideal for apparel and large banners.

Best use cases for each method: Digital printing is best for detailed graphics, short runs, and quick turnarounds. Screen printing is ideal for large orders, simple designs and items such as t-shirts and posters.

Digital printing technology

Types of digital printers: inkjet printers, which spray droplets of ink onto paper, and laser printers, which use toner and lasers to create images.

Advances in digital printing technology: Improvements include higher resolution printing, faster printing speeds, and more durable and vibrant inks.

Software and digital workflow integration: Modern digital printers are integrated with software that allows for efficient workflow management, color correction and printing directly from design programs.

Trends and future developments: Trends include eco-friendly inks, the development of 3D printing, and printers that can print on different materials beyond traditional paper.

Digital Printing Advantages and Disadvantages

Benefits

Quick turnaround times

Speed: Digital printing does not require a lengthy set-up process of making plates, as offset printing does. Once the file is ready, it can be sent directly to the printer, significantly reducing the time from concept to finished product.

Efficiency: This fast process is ideal for tight deadlines, making it possible to fulfill orders quickly.

Customization and personalization

Variable Data Printing: Digital printing allows for easy customization on each printed piece. For example, in direct mail campaigns, each piece can have a unique name, address, or even personalized messages without slowing down the printing process.

Marketing and Branding: This ability is invaluable for personalized marketing content, enabling brands to engage with their audience on a more personal level, potentially increasing response rates and customer loyalty.

Cost effectiveness for short runs

No Setup Costs: Traditional printing methods incur setup costs for making the plates and aligning them properly. Digital printing skips this step, making it much more economical for small print runs.

Flexibility: You can print as much as you need without worrying about inefficiencies, reducing over- or under-production, waste and storage costs.

Minimal setup and preparation

Simplicity: Digital printing is straightforward and user-friendly. The process involves less manual intervention, reducing the risk of human error and ensuring consistent production.

Ease of use: With digital files, last minute design changes or updates are easy and do not involve additional costs or delays, unlike traditional methods where changes require new plates.

Disadvantages

Higher cost per unit for larger volume

Economies of scale: For very large print runs, the cost per unit can be higher with digital printing than with offset printing. This is because in offset printing, the initial setup costs are spread over a large number of prints, making each additional print cheaper.

Long-term cost: While digital printing is great for small batches, businesses that regularly need large quantities may find it less cost-effective over time.

Limitations in color matching and specialty inks

Color Accuracy: Digital printers can struggle with exact color matching, especially when reproducing brand-specific Pantone colors. Offset printing, in contrast, allows precise color matching using a wider range of inks.

Special effects: Digital printers may have limitations with certain inks, such as metallics, fluorescents, or spot UV finishes, which are more easily achieved with traditional printing methods.

Potential for low stability

Print longevity: Digital prints, especially from inkjet printers, may not be as durable as those produced by traditional methods. They can be more susceptible to fading over time, especially when exposed to light and environmental conditions.

Material compatibility: Although digital printing is versatile, some materials may not hold digital ink as well as traditional ink, potentially causing issues such as fading or reduced longevity in some applications.

Types of digital printing

Inkjet Printing:

Overview and Applications: Uses nozzles to spray ink onto paper, ideal for high quality photo prints and small to medium print runs.

Pros and Cons: Pros include high quality color and detail. Disadvantages include slower print speeds and higher ink costs.

Laser printing:

Overview and Applications: Uses a laser to transfer toner to paper, suitable for high-speed printing of text and graphics.

Advantages and Disadvantages: Advantages include faster printing speed and lower cost for large volumes. Disadvantages include limited color range compared to inkjet.

Digital Presses:

Overview and Applications: Includes printers designed for specific materials or applications, such as 3D objects or fabric.

Advantages and Disadvantages: Advantages include the ability to print on a variety of materials and create unique products. Disadvantages include high cost and special requirements.

Specialized digital printing (eg, 3D printing, textile printing):

Overview and Applications: Includes printers designed for specific materials or applications, such as 3D objects or fabric.

Advantages and Disadvantages: Advantages include the ability to print on a variety of materials and create unique products. Disadvantages include high cost and special requirements.

FAQ

How does digital printing differ from traditional printing methods like offset printing?

Digital printing doesn’t need setup plates and is cheaper for small batches. Offset printing uses plates and is more cost-effective for large runs.

What materials can be printed using digital printing?

Digital printing can be done on paper, fabric, plastics, vinyl, and specialty materials like canvas and wood.

When should I choose digital printing over other methods?

Use digital printing for short runs, personalized items, quick turnarounds, and when you need to save on setup costs.

Is digital printing environmentally friendly?

Yes, many digital printers use eco-friendly inks and materials, and print on demand reduces waste.

Can digital printing handle high-quality photo printing?

Yes, especially with high-resolution inkjet printers that produce vibrant and detailed photos.

1 thought on “What is digital printing? And its Types”