In this article, we explore the world of label printers, exploring their functionality, features, applications, and future trends. Whether you’re a business owner, warehouse manager, or healthcare professional, understanding label printers is key to increasing efficiency and professionalism in your operations.

Labels are essential tools in all industries, providing important information for communication, identification, and organization. From retail to manufacturing, from healthcare to logistics, labels are everywhere, helping with product specifications, pricing, and inventory management.

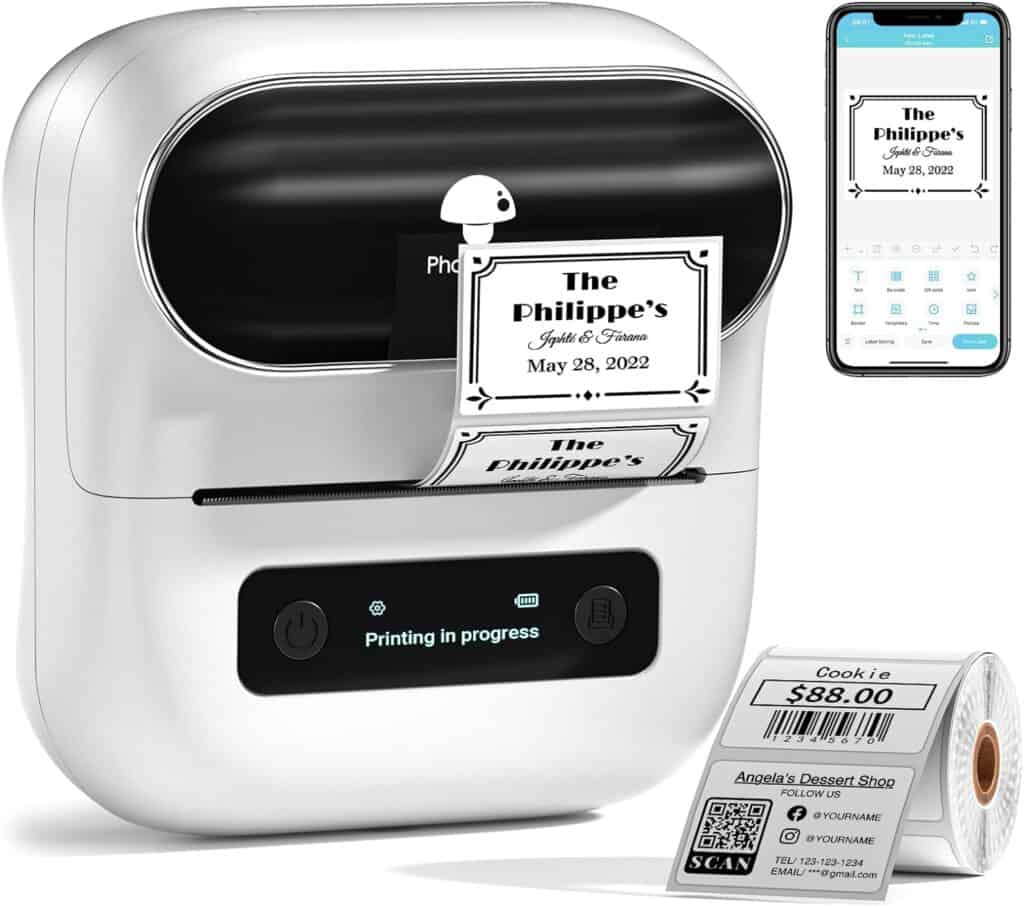

Label Printers – Specialized devices that are completely designed to produce labels of different sizes, materials and types. Unlike regular printers, label printers are designed for this specific task, ensuring high-quality, professional results every time.

Table of Contents

What is label printers?

Label printers are specialized devices that are different from regular printers. They are specially designed to produce labels of different sizes, materials, and types.

Types of Label Printers:

Desktop Label Printers are compact models suitable for small-scale printing needs. They are often used in home offices or small businesses.

Industrial Label Printers: Robust machines designed for high-volume printing in manufacturing, warehouse, and logistics environments.

Portable Label Printers: Lightweight, handheld devices ideal for on-the-go printing jobs, commonly used in field service, retail, and healthcare settings.

Advantages of regular printers:

Accuracy: Label printers offer high print quality and resolution, ensuring crisp, clear labels

Performance: They are optimized for faster printing speeds, increasing productivity, especially in high-volume settings.

Special features: Label printers come with features designed for label printing, such as specific connectivity options and compatibility with label materials.

Applications:

Industrial: Used for inventory management, asset tracking, and product labelling in manufacturing and logistics.

Retail: Employed for pricing, product labelling, and barcode printing to streamline sales and inventory management processes.

Healthcare: Labelling medical specimens, patient records, and prescriptions is critical to facilitating accurate identification and tracking.

Office: Used for address labels, file organization, and mailroom management to increase organization and efficiency.

Key Considerations:

Resolution and Print Quality: Choose high-resolution printers for clear, professional-looking labels.

Printing Speed: Choose models with faster printing speeds to speed up labelling tasks.

Connectivity Options: Look for printers with versatile connectivity options, such as Wi-Fi, Bluetooth, USB, or Ethernet, for seamless integration with various devices.

Label Compatibility: Ensure compatibility with a wide range of label sizes, materials and types to meet different labelling needs.

Software Compatibility: Choose printers compatible with popular label design software for easy customization and design flexibility.

Key Features to Look for in Label Printers

Resolution and Print Quality:

Excellent print resolution ensures labels are clear, sharp, and professional-looking, enhancing readability and brand image.

Printing speed:

Faster printing speeds increase productivity, especially in high-volume environments, reduce wait times and increase efficiency.

Contact Options:

Versatile connectivity options such as Wi-Fi, Bluetooth, USB, and Ethernet enable seamless integration with various devices and networks, facilitating easy printing from multiple sources.

Label Compatibility:

Ensure compatibility with a wide range of label sizes, materials and types to accommodate diverse labelling needs, providing flexibility and versatility in label creation.

Software Compatibility:

Compatibility with popular label design software allows easy customization and design flexibility, empowering users to create professional-looking labels tailored to their specific needs.

Applications of label printers

Industrial Applications:

In manufacturing, label printers are indispensable for inventory management, asset tracking, and product labelling, ensuring efficient operations and accurate inventory control.

Warehousing and logistics leverage label printers to label packages, pallets and shelves, streamlining movement and tracking goods in the supply chain.

Retail Applications:

Retailers use label printers for pricing, product labelling, and barcode printing to facilitate smooth transactions and accurate inventory management.

Labels play an important role in branding and product identification, enhancing the customer experience and promoting sales.

Healthcare Applications:

In healthcare settings, label printers are critical for labelling medical specimens, patient records, and prescriptions, ensuring accurate identification and tracking of patient information.

Pharmacy label printers enable clear and accurate labelling of medication containers, reducing the risk of medication errors and improving patient safety.

Office Applications:

Label printers are essential in office environments for addressing envelopes, organizing files, and increasing the management, organization, and efficiency of mailrooms.

Custom labels for file folders, storage boxes, and office supplies help improve classification and retrieval, workflow and productivity.

Future trends in label printing

Advances in Label Printing Technology:

Continuous innovations in label printing technology are increasing print quality, speed and efficiency.

Emerging technologies such as UV printing, LED curing, and digital jewellery are revolutionizing the label design and production process, offering new creative possibilities and high-quality finishes.

Integration with IoT and Automation:

Label printers are increasingly integrated with Internet of Things (IoT) devices and automation systems, enabling real-time monitoring, data collection, and remote management of the printing process.

Automation of label printing operations increases efficiency, reduces errors, and enables adaptive manufacturing processes to meet specific needs and demand fluctuations.

Sustainability measures:

The label printing industry is witnessing a shift towards more sustainable practices due to environmental concerns and consumer demand for eco-friendly products.

Manufacturers are looking to eco-friendly label materials, such as biodegradable substrates and water-based inks, to reduce environmental impact and meet sustainability goals.

Customization and Personalization:

The growing demand for personalized products and packaging is driving the need for custom label printing solutions.

Digital printing technologies enable on-demand printing of customized labels with variable data, allowing brands to create unique and targeted packaging designs for individual products or customer segments.

Smart Label Technologies:

Smart labels incorporating RFID (Radio Frequency Identification) and NFC (Near Field Communication) technologies are gaining attention for improved product tracking, authentication, and customer engagement.

These technologies enable brands to provide consumers with access to product information, promotions and interactive experiences through smartphone apps and other digital platforms.

FAQ

What are label printers used for?

Label printers are used to produce labels of different sizes, materials, and types for various applications such as inventory management, product labeling, pricing, and organization.

How do label printers differ from regular printers?

Label printers are specialized devices designed specifically for printing labels, offering features like high-resolution printing, compatibility with label materials, and faster printing speeds compared to regular printers.

What types of label printers are available?

There are three main types of label printers: desktop label printers for small-scale printing needs, industrial label printers for high-volume printing, and portable label printers for on-the-go printing tasks.

What are the key features to consider when choosing a label printer?

Key features to consider include resolution and print quality, printing speed, connectivity options, label compatibility, and software compatibility.

How can label printers contribute to increasing efficiency in operations?

Label printers enhance efficiency by providing clear, professional-looking labels quickly, streamlining tasks like inventory management, product labeling, and organization, thereby saving time and reducing errors.

What are the emerging trends in label printing technology?

Emerging trends include advances in printing technology like UV printing and digital embellishment, integration with IoT and automation for real-time monitoring, and sustainability measures such as eco-friendly label materials.

What are the benefits of using label printers in retail environments?

In retail, label printers facilitate pricing, product labeling, and barcode printing, enabling smooth transactions and accurate inventory management, while also enhancing branding and product identification.

What role do label printers play in personalized product packaging?

Label printers enable on-demand printing of customized labels with variable data, catering to the growing demand for personalized products and packaging, and allowing brands to create unique experiences for consumers.

A label printer offers specialized functionality for efficiently printing labels, enhancing organization and productivity. Its distinct design and features cater specifically to label printing needs, providing convenience and accuracy.

Thank You soo much for providing best information about Label Printers. Label Printer helps us to work more efficiently, manage stock easily.I think label printers are now necessary part of shops.

Play Against the Best in This Action-Packed Poker Game!

game roulette casino http://www.casinowild-24.com/games-guide/roulette-guide/ .